News

FomaPan 200 Creative Test Data

Tim Gilbert

UPDATE: here's a link to our Foma Data page: https://shop.stearmanpress.com/pages/film-data-foma Overview: We've been testing FomaPan 200 Creative with our SP-76EC developer. The above curves are from a standard 21 step tablet and measured with a densitometer. All shots taken with a calibrated shutter. Click above to download a larger version. The Film: Foma boasts that this is a new generation film. It features hexagonal core/shell tabular silver halide grains that is supposed to have better resolving power and lower granularity. So kind of like TMax but only kind of. What we've seen so far, we like. However, we really wanted...

26 years too late...

Tim Gilbert

It's a long story but I've accidentally acquired 300' of Kodak Tri-X 35mm film. It expired in 1993 but had been stored in a sealed plastic tub in a basement up in the Colorado mountains. Now what? Frankly, I don't shoot much 35mm (so don't ask why I went to the effort to "acquire" this. I just couldn't resist.) Anyway, I've shot a few rolls (at ISO 200) and played around with developers. It's a bit grainy (no surprise), lots of fog (0.64 according to my densitometer) but it's still usable. The above were processed in Xtol 1:1;...

Kodak Ektascan B/RA X-ray film testing

Tim Gilbert

We've been playing with Kodak's Ektascan Xray film. Cool stuff. It has a tabular grain (rumor is that it's the same emulsion as their TMax but without the panchromatic dyes) and is single sided. And cheap, about a buck a sheet for 8x10. Of course, it's orthochromatic and we were curious about its spectral response but couldn't find anything definitive on the web. So we did a quick test. Here's the standard Macbeth color checker as seen by Ektascan (we added the labels.) In case you forgot, here's the color version: As you can see, (unless you're color blind), Ektascan...

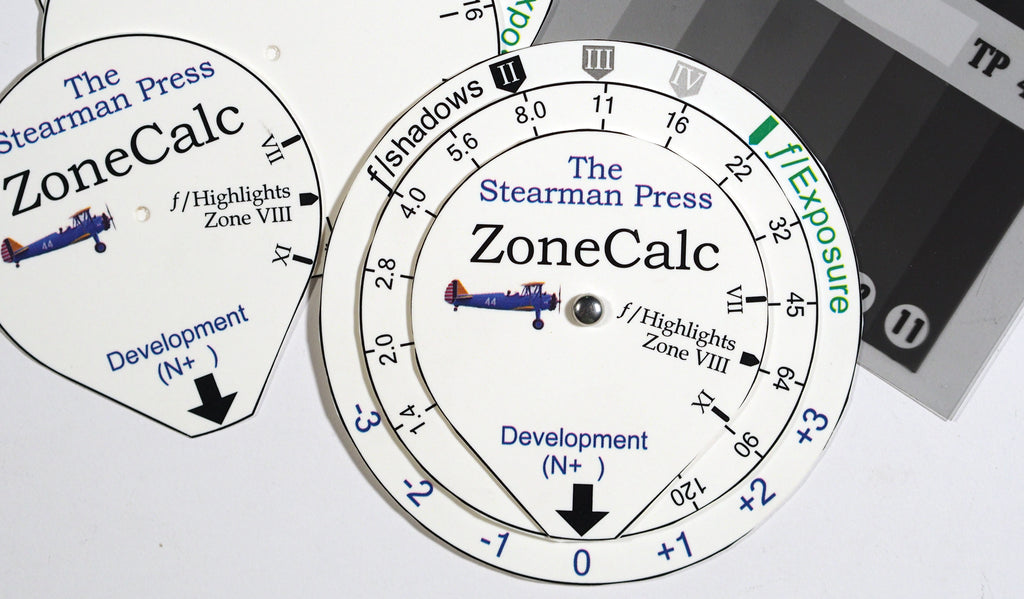

The ZoneCalc: simple zone system calculator

Tim Gilbert

Maybe it's just me? Maybe everyone else can take a bunch of light readings and 'see' exactly where everything lands on the sacred zone scale and how they relate to each other. Maybe I just need more practice? After all, the math is pretty simple.Whatever the case, I accidentally invented the ZoneCalc. Accidentally is a polite word; I was really supposed to be working on something else but got distracted. In the middle of my distraction, while staring at my scribbles and sketches, I realized that I was really close to creating something useful. Hence the ZoneCalc was born.Granted, the...

Butchering a SP-8x10

Tim Gilbert

We cut up another perfectly good prototype. It wasn't quite as painful given that this is the lid from the previous unit we sacrificed but it still stings a bit. We really wanted to see how the film behaved when the tray was full of liquid. The easiest solution was to cut some windows. This allowed us to watch the film while filling, agitating and draining the tray. Turned out to be a waste of a good lid. The film hold down tabs performed just as we hoped. At least now we know.